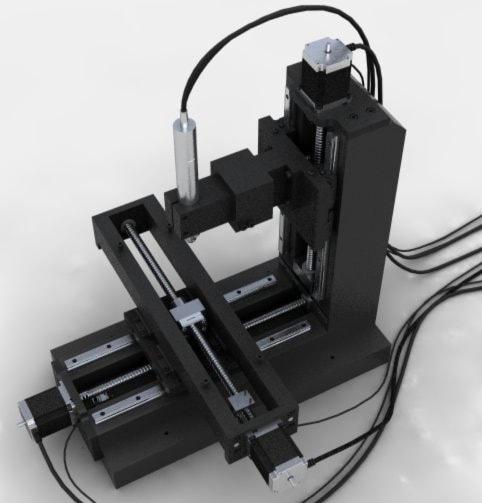

The GX is available as a standard three axis machine with optional 4th Axis Rotary Stage, or 5 Axis Trunnion Table.

The Minitech CNC Mini-Mill/GX is the most affordable precision-ground, granite frame, micro machining system on the market.

Minitech builds these machines using THK caged-ball linear bearings and high precision ball-screws for all stages. Each base is precision ground, polished and aligned to the micron level.

The Natural Granite construction offers excellent stability and strength along with a high degree of vibration dampening and thermal stability benefits not found in any other material. The GX is ideal for Microfluidic, Micro-electromechanical, Nanotechnology Industries, Jeweler, Research Laboratories and many others.

Hundreds sold in over 30 countries worldwide. Available 3, 4 and 5 axis

Machine Specifications

| Specifications | Imperial | Metric |

| Overall Size – Static | 22″ x 22″ x 23″ LWH | 560mm x 560mm x 585mm LWH |

| Table-top Size | 20.0″ x 6.0″ | 508mm x 152.4mm |

| Table-top Hold Down Type | 1/4-20 mounting holes on 1″ centers | M6 threads |

| X,Y,Z Travel | X = 12.0″ Y = 9.0″ Z = 9.0″ | X = 300mm Y = 200mm Z = 200mm |

| Feed-rates, high-resolution mode | 0.1 to 50 inches per minute | 0.1 to 1,200 mm per minute |

| Resolution, minimum commanded movement, high-resolution mode | 0.0001″ | 0.0001 mm |

| Machine Weight | 225 Lbs. | 110 Kg |

Superior Grade Components

Dual linear ball bearing slides on each axis, sealed. THK(tm) linear slides – Caged-ball technology

THK(tm) Ball Screw actuator – preloaded and sealed, 5mm pitch, this model achieves no torque fluctuation and no backlash, Positioning repeatability of the ball screw is 0.0004mm, 16mm diameter, 5mm pitch

Solid black granite, precision ground base

The GX is available as a standard three axis machine with optional 4th Axis Rotary Stage, or 5 Axis Trunnion Table.

Manufactured by Minitech in the USA for worldwide distribution.

Machines can be modified to meet your specific needs.